Relocation repeatability was assessed as described in the page on Stage Metrology, except that stage control and image acquisition were done by this MATLAB script. The tests were performed on Olympus BX51 microscope using an England Finder slide. Objective - UPlanFL 4X/0.13, camera - AVT Manta G282C mounted in the primary image plane (no relay lens). Pixel size with this setup was 1 μm. Tests were performed with 24V power supply after the system has been used for about one hour at about half of maximal stage speed (15 mm/sec).

The target position was chosen approximately in the middle of each of the four bays of the stage. The relocation sequence consisted of two parts: approaching the target position from top left and approaching the target position from bottom right; each repeated 50 times. The move to target position was from 5 mm afar in X and Y. This method of testing relocation in our view is closer to the real usage of a stage in a microscope system than testing X and Y axes individually. The measured errors in this case include both on-axis and off-axis errors of the stage.

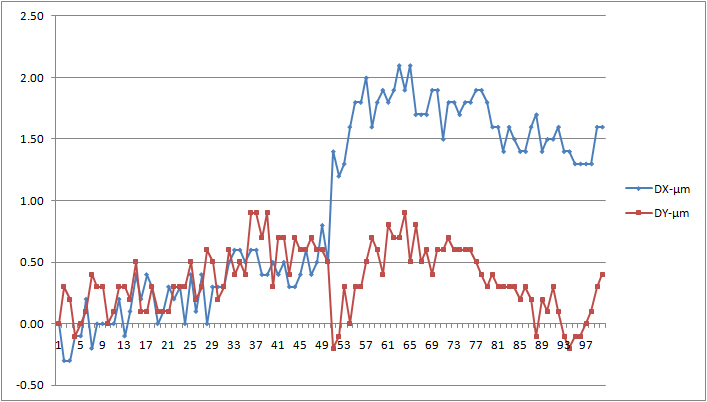

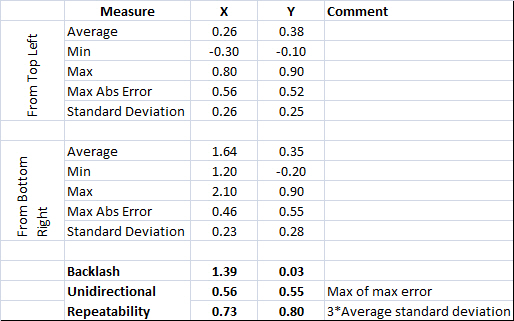

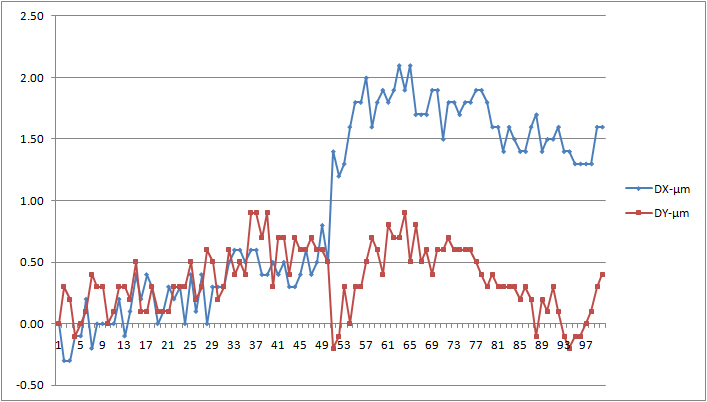

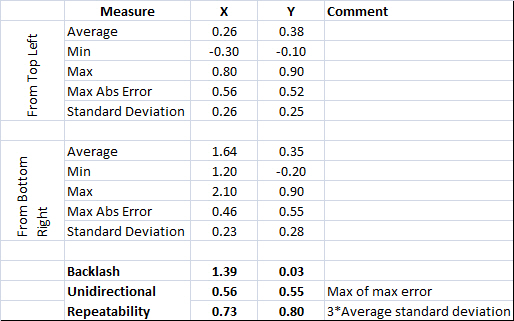

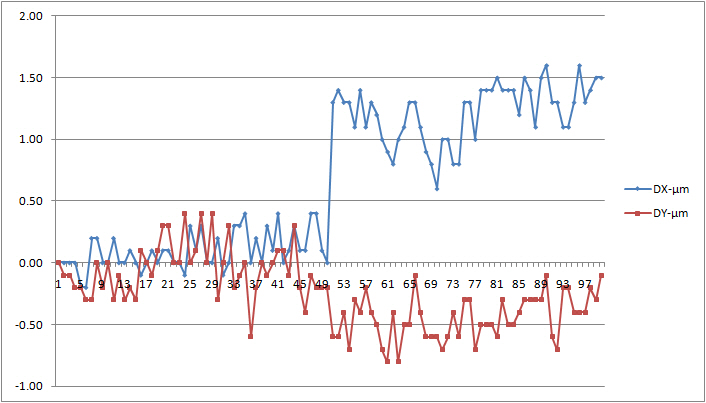

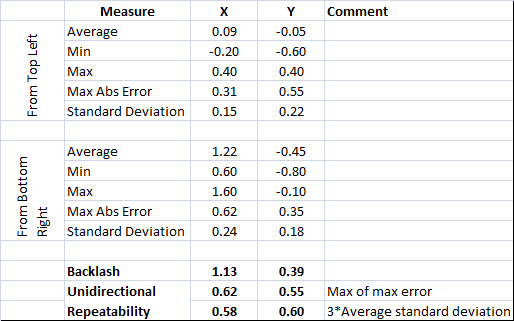

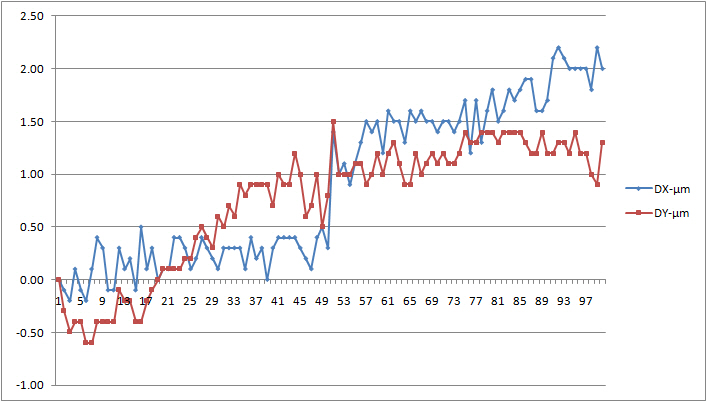

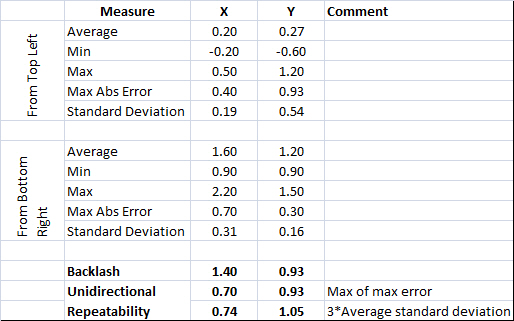

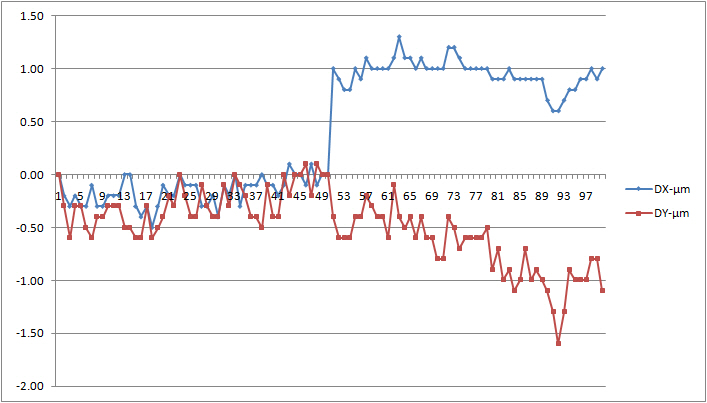

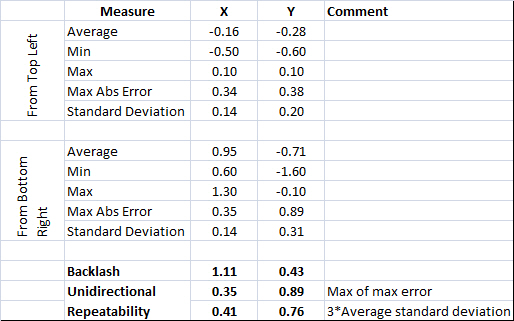

Relocation errors were estimated with a purpose-written software that calculates shifts between images with sub-pixel accuracy (0.1 of pixel size). Relocation errors from individual repetitions of the test recalculated in microns are given by the following plots. Backlash was calculated as the difference between average values in top-left and bottom-right series. Unidirectional repeatability has two numerical measures: maximal deviation from the average and standard deviation multiplied by 3.

Bay 1

Bay 2

Bay 3

Bay 4

Home > Motorized 4-Slide Stage with Integrated Controller > Relocation Repeatability