Relocation

repeatability tests were performed on Olympus BX51 microscope using a custom

calibration slide with patterns created by metal vapor-deposition. Objective - UPlanFL 10X/0.30, camera - Canon 40D mounted in primary image plane (no relay

lens). The camera was connected to computer with USB cable and controlled by

Canon Utility program. During acquisition the camera was set in Live View mode. Pixel size with this setup was 0.575

μm. Relocation target was a pattern of

32μm*32μm

squares shown in the picture. Tests were performed with 36V power supply after

the system has been turned on for about one hour. Stage movement and overall

control was done by the following script written in the

ScopeTool interpreted language:

XY Home ; XY Wait ;

Repeat 100 Times

XY 7000 25000 ; XY Wait ; ! Top

Left Parking Position ;

XY 12000 30000 ; XY Wait ; ! Target Position ;

Snap ; Delay 4000 ;

! Target Image Approached from Top Left ;

Endrepeat

Repeat 100 Times

XY 17000 35000 ; XY Wait ; ! Bottom Right Parking Position ;

XY 12000 30000 ; XY Wait ; ! Target

Position ;

Snap ; Delay 4000 ; ! Target Image

Approached from Bottom Right ;

Endrepeat

The target position was

randomly chosen in the field of squares. The relocation sequence consisted of

two parts: approaching the target position from top left and approaching the

target position from bottom right; each repeated 100 times. The move to target

position was from 5 mm afar in X and Y with speeds 24 mm/s in X and 48 mm/s in Y

and acceleration 950 mm/s2 in both X and Y. (Distance numbers in the

script are in microns and time is in milliseconds). This method of testing

relocation in our view is closer to the real usage of a stage in a microscope

system than testing X and Y axes individually. The measured errors in this case

include both on-axis and off-axis errors of the stage.

Camera control in the script (the Snap command) was achieved by sending key strokes to the Canon Utility program, that correspond to the shutter release and waiting for the image transfer to complete. Some of the key strokes were lost and the total number of collected images is slightly smaller than 200.

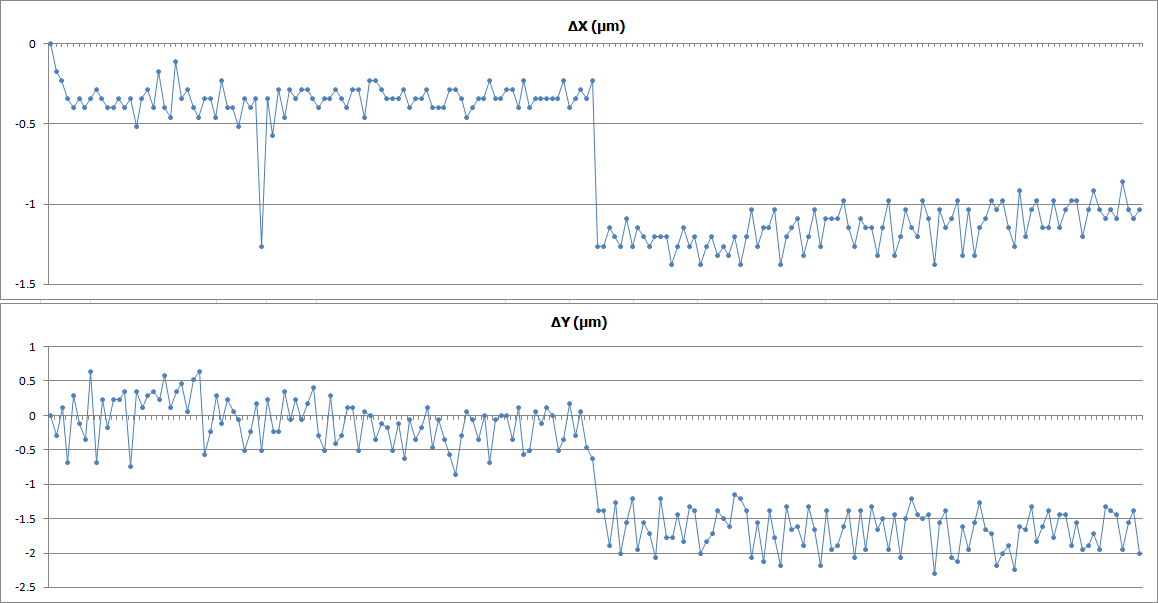

Assessment of relocation was done with a purpose-written software that calculated shifts between images with sub-pixel accuracy (0.1 of pixel size). Relocation errors from individual repetitions of the test recalculated in microns are given by the following plots. Backlash was calculated as the difference between average values in top-left and bottom-right series. Unidirectional repeatability has two numerical measures: maximal deviation from the average and standard deviation multiplied by 3.

Home > Motorized Stage with Integrated Controller > Relocation Repeatability